A new generation of high performance aluminum alloy - aluminum-scandium alloy

【Summary】: Aluminum alloy is an important engineering material for national economic construction and security. As the world’s aluminum alloy materials develop towards high-performance directions such as high strength and high toughness, in addition to meeting the needs of military industries such as aerospace and some special industrial sectors, a series of new civilian aluminum alloy materials with various properties and functions that can meet different conditions and uses are also developed. Aluminum has been an important basic material for aerospace engineering for a long time due to its low density and cost. However, the performance of pure aluminum cannot meet the requirements of aerospace materials for strength, toughness, and corrosion resistance on many occasions, so people try to add various alloy elements to pure aluminum to improve the performance of aluminum materials. However, so far, some key technologies for the preparation of high-performance aluminum alloys in China have no breakthroughs. The high-performance aluminum alloy materials required for many key models still rely on imports. The research and development of high-performance aluminum alloys needs to be further improved, and the research on aluminum-scandium alloys has brought new opportunities to aluminum alloys!

1.Overview of Aluminum-Scandium Alloy

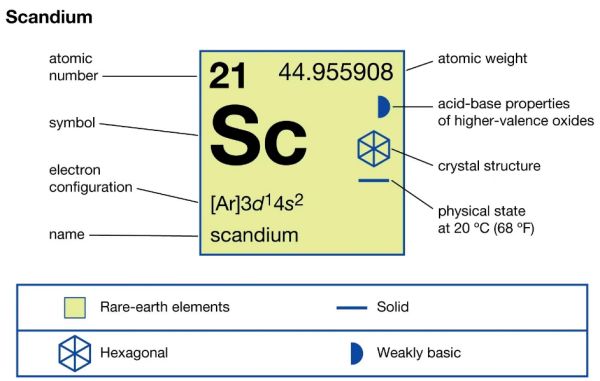

Scandium, element symbol Sc, atomic number 21, is the first transition element in the fourth period of the periodic table and belongs to Group IIIB. Aluminum, element symbol Al, atomic number 13 in the periodic table, is a metal element in Group IIIA, with a relative density of 2.7g/cm³, a melting point of 660℃, and a boiling point of 2327℃.

Figure 1 Introduction to Scandium

China has become the largest producer and consumer of the aluminum industry but still has been at the middle and low end of the aluminum industry chain. There are few high-end alloy materials independently developed, and high-end products rely heavily on imports. High-end casting aluminum alloys, represented by Al-Cu and Al-Zn series, have remarkable characteristics such as high strength and good casting performance. However, the cost for the use of rare elements is bit high, limiting the application of aluminum alloys. Since the 1990s, Russia has invested heavily in the development of aluminum-scandium alloys, currently in a leading position in the world aluminum-scandium alloy market, with 10 series and 40 grades of aluminum-scandium alloys, and has formed AI-Mg-Sc, AI-Zn-Mg-Sc, AI-Zn-Mg-Cu-Sc, AI-Mg-Li-Sc, and AI-Cu-Mg-Sc series deformed aluminum alloys, and the scandium content is only 0.18% to 0.5%. China started late in the development of aluminum-scandium alloys and currently has only two grades, which is a big gap compared with Russia.

In 2020, the world's Sc reserves are about 2200kt, of which 90% to 95% are found in bauxite, phosphorite, and ilmenite, mainly distributed in Russia and China. Pure Sc is silver-white with a slight yellow tint and has a metallic luster. It is quite soft and can be rolled into thin sheets without annealing. Although the amount of Sc and its compounds are not large, their application areas are very wide, involving all areas of materials, such as non-ferrous metal alloy materials, electric light source materials, precision ceramics, solid electrolytes, catalytic materials, nuclear industry materials, laser crystals, semiconductors, and superconducting materials.

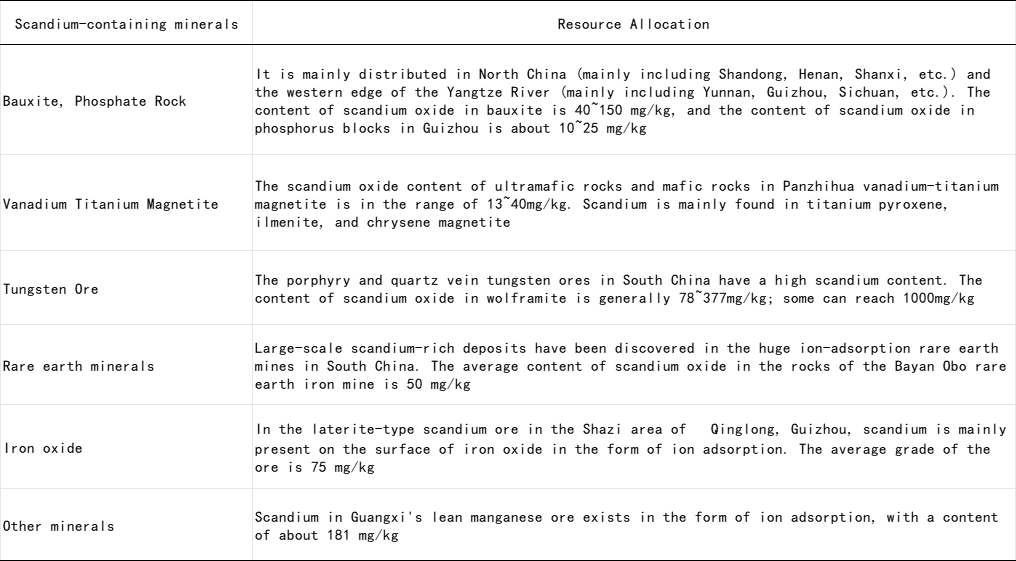

Table 1 Distribution of major scandium-containing minerals in China

Source: Overview of China's Scandium Ore Resources and Suggestions for Industrial Development

In terms of the research development and application of Al-Sc alloys, the former Soviet Union and Russia are at the forefront, and have developed a series of aluminum-scandium alloys with excellent performance, such as the 1420 alloy, which has been widely used in aircraft structures; the 1421 alloy is an Al-Mg-Li-Zr-Sc alloy containing Sc, and the extruded profiles have been used to manufacture the longitudinal beams of transport aircraft fuselages and have been well received.

Figure 2 Aluminum-scandium alloy plate

Effects of Scandium on Aluminum Alloy

According to the research of D.G. Eskin, a scientist at Brunel University in the UK, Sc is the best refiner for aluminum and aluminum alloys and has the greatest refinement effect. Sc and 15 elements of the Y and La series belong to the III B group of the element period. Its main chemical properties are similar to those of the Y and La series elements, and they have the same oxidation state. The lattice constant, density, and some physical and mechanical properties of scandium are close to those of aluminum, making it an ideal alloying element for aluminum alloys. The density of scandium is only 2.99 g/cm³, and it belongs to the same light metal as aluminum. Moreover, it has a much greater strengthening effect on aluminum alloys than other elements. As a transition element and rare earth element, it can not only significantly refine the cast alloy grains, increase the recrystallization temperature, and thus improve the strength and toughness of aluminum alloys, but also significantly improve the weldability, heat resistance, corrosion resistance, thermal stability and resistance to neutron radiation damage of aluminum alloys. Therefore, aluminum-scandium alloy is considered to be a new generation of high-performance aluminum alloy structural material for aerospace and ships.

Sc has a magical effect on the grain refinement of aluminum and aluminum alloys. Just adding a few thousandths of Sc will produce Al3Sc intermetallic phase, which has a significant grain refinement effect on aluminum and aluminum alloys, and can significantly improve the high-temperature strength, structural stability, weldability, and corrosion resistance of the alloy, and avoid the embrittlement phenomenon that is easy to occur during long-term high-temperature operation, thereby greatly improving its organization and performance.

A small amount of scandium can significantly change the properties of aluminum alloys. Scandium has a good dispersion-strengthening effect on aluminum and maintains a stable non-recrystallized structure in the state of hot processing or annealing. The inhibitory effect of scandium on recrystallization can eliminate the recrystallized structure in the heat-affected zone of the weld so that the welded joint containing aluminum-scandium alloy has higher strength and corrosion resistance. At the same time, the improvement of the corrosion resistance of aluminum alloy by scandium is also due to the refinement of grains and the inhibition of the recrystallization process by scandium. Adding scandium can also make aluminum alloy have good superplasticity. After superplastic treatment, the elongation of aluminum alloy with about 0.5% scandium can reach 1100%. For example, the yield strength of aluminum-scandium alloy is 150% higher than that of aluminum-magnesium alloy, and it can maintain density and corrosion resistance at the same time. In addition, scandium also increases the quality of alloy welded joints, avoids weld cracking, and increases fatigue life by 200%. Therefore, aluminum-scandium alloy is expected to become a new generation of lightweight structural materials for the aerospace, aviation, and shipbuilding industries.

Figure 3 Aluminum-scandium alloy molded parts

EN

EN NL

NL FR

FR DE

DE JA

JA KO

KO PT

PT RU

RU ES

ES TR

TR